At Flintco Industrial, we’ve embraced technology to unleash more productivity during preconstruction, created more certainty around schedule and manpower while making your project more accessible and intuitive.

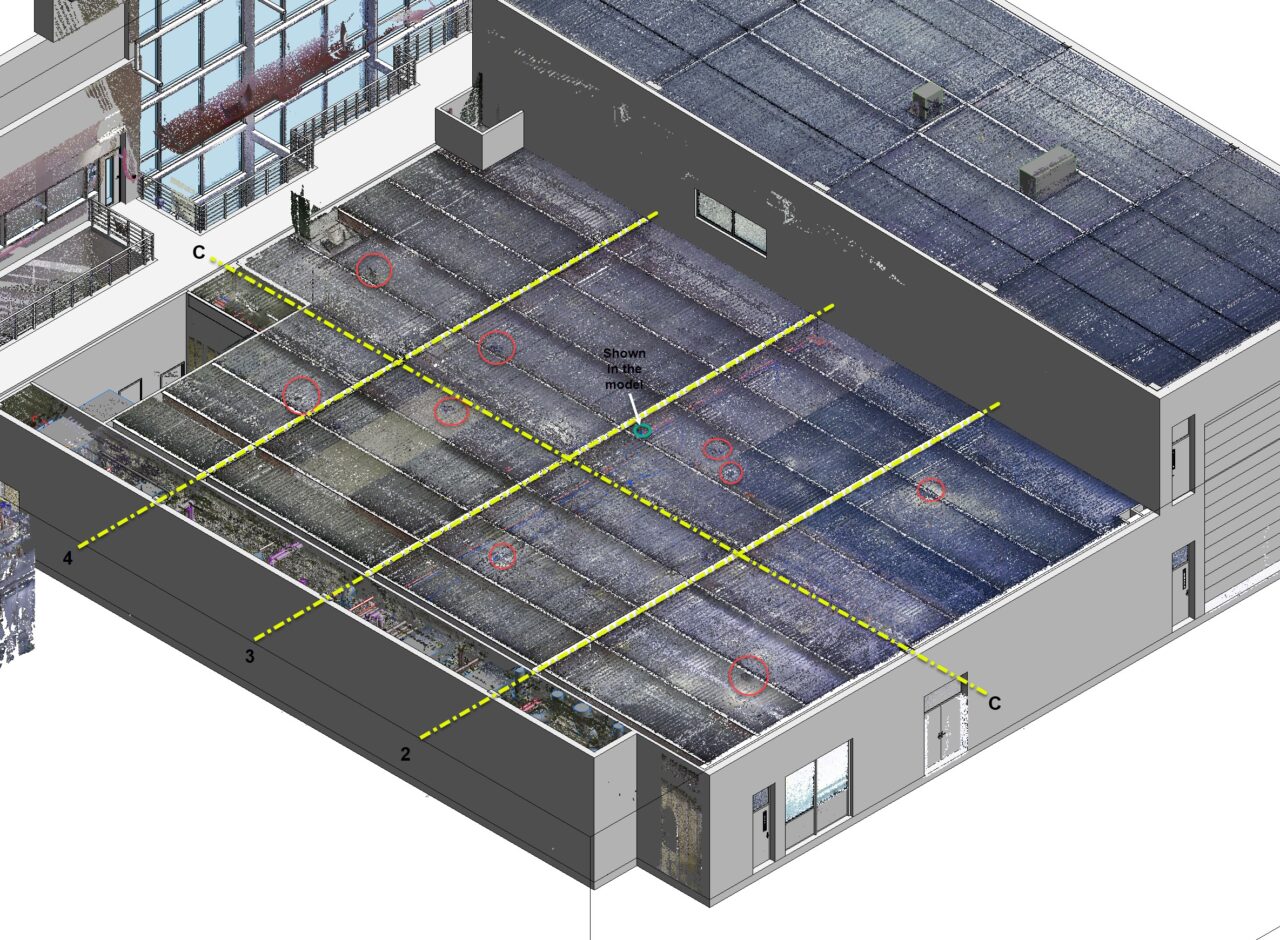

Our Preconstruction teams acquire quantity takeoffs instantaneously using Assemble software to interact with the BIM model. The time savings and accuracy of the data is astonishing! By removing obstacles – a Lean 2.0® practice – we capture more time to focus on what truly helps bring your project closer to reality by accounting for scope and budget not shown in the current state of design. Flintco superintendents also employ other Lean practices to visualize the schedule in 3-D using a color-coded model organized into trade packages, then into manageable sizes of scope assigned to appropriate periods of time. Visualizing the project schedule through the model allows the team to be more proactive: we work together on a collaborative plan, removing all constraints and begin moving together at the pace directed by the baseline schedule.

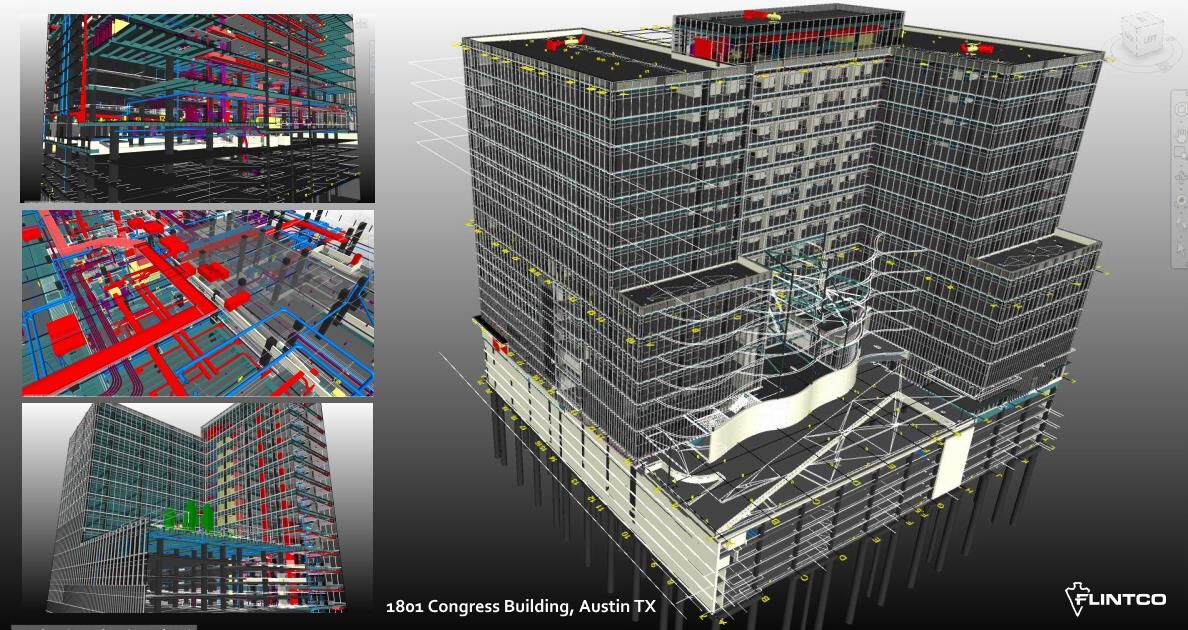

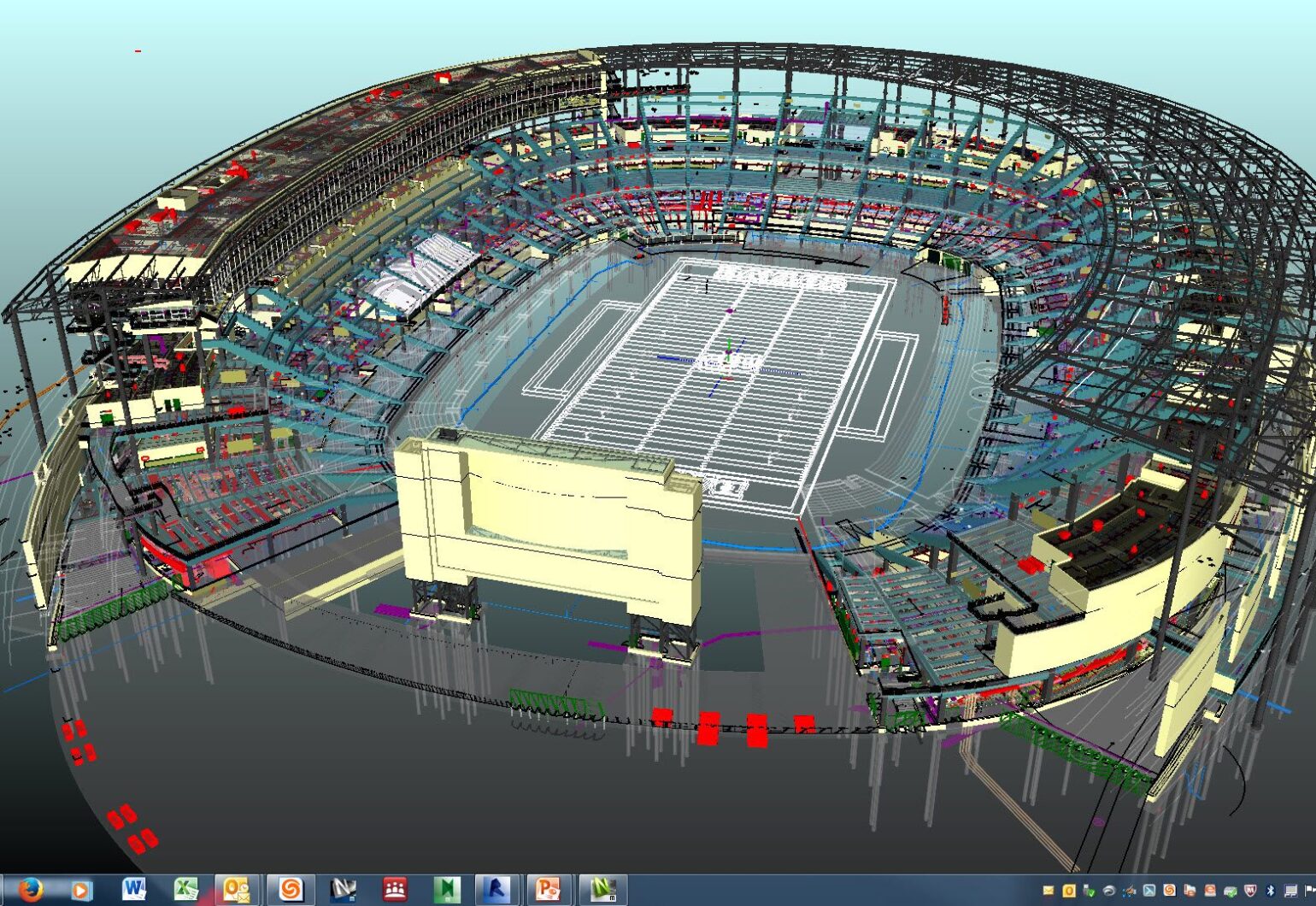

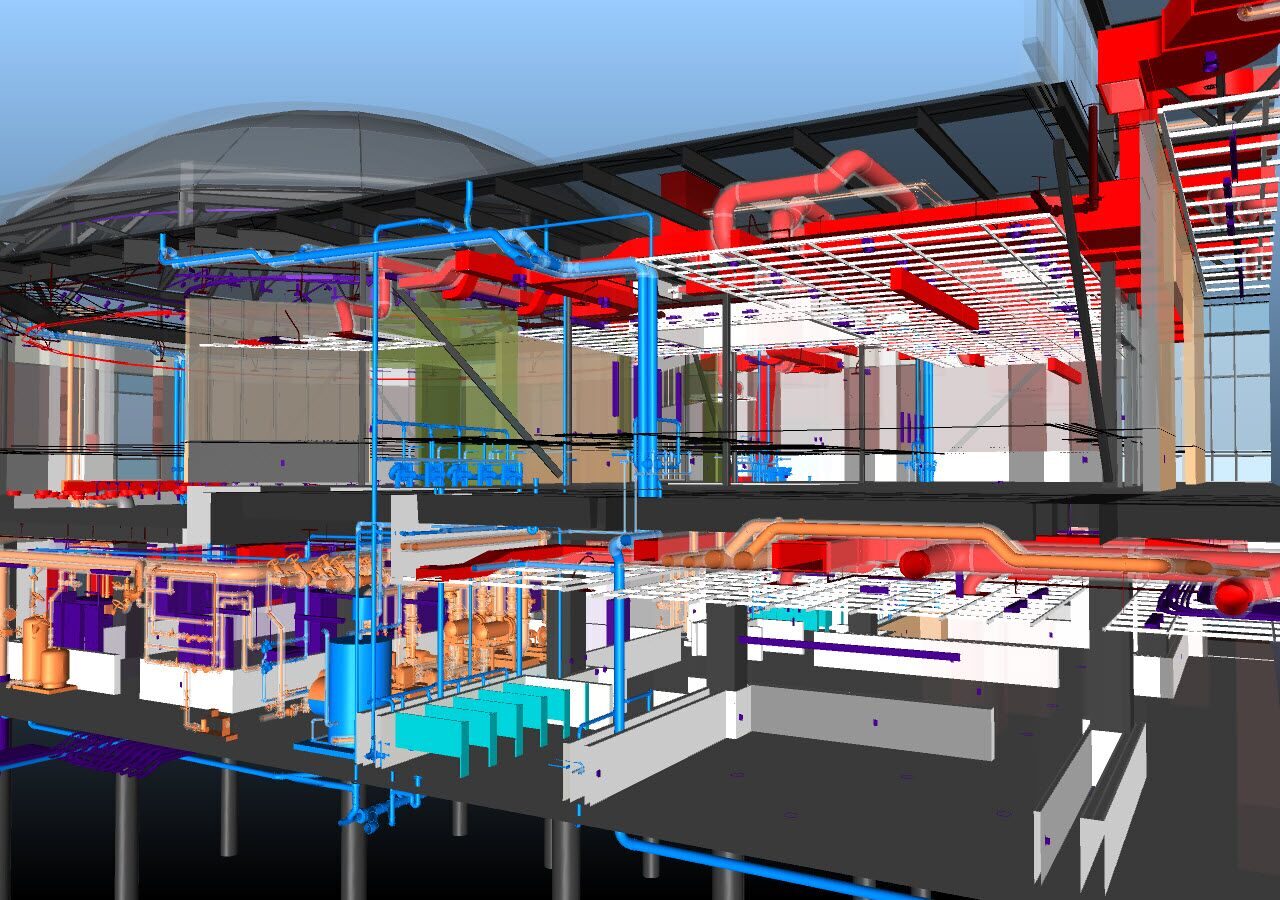

We have cut the time it takes to complete clash detection by more than 50% – by improving our work flows and employing experienced VDC technologists who are dedicated to understanding both architecture and construction, which leads to more productive collaboration without compromising design intent. Our VDC managers attend every scheduled Building Information Modeling (BIM) meeting via webcast or in person, providing solutions to clashes with an understanding of owner requirements, the design and contract terms to recognize when means and methods affect costs and when they don’t. Flintco uses technology in conjunction with your design team to anticipate potential conflicts, and to quickly present solutions that protect the integrity of your project. Our team conducts early constructability reviews with in-house subject matter experts, working alongside the design team to ensure design and construction always remain in sync. Flintco combines models generated by the design team and trade partner shop drawing models for construction coordination. We track every clash detected through weekly model updates, clash detection tests, and publish a viewable model that documents each clash. The result – certainty that saves time and money while improving quality and enhancing safety.

As early as Design Development, Flintco begins reviewing the design team models, led by an in-house Virtual Design and Construction manager. Early involvement and coordination reviews by our VDC team helps ensure quality control and mitigates change orders once construction commences.

As the design continues to progress through Design Development (DD), our Preconstruction Manager and MEP & Commissioning Manager are more actively involved in the design review as cost estimates are developed that lead to the Guaranteed Maximum Price (GMP). Our project management team leads constructability reviews throughout DDs. Our early involvement, and collaboration with the design team is essential to the overall success of your project.